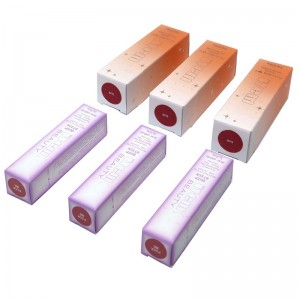

Cosmetics Boxes Packaging, Skincare Boxes Packaging

Specification

| Size: | Customized, we accept any size accordingly to requsted. |

| Colour Options: | CMYK/ PMS/ UV printing, Silk screen printing, Metallic color printing, Film printing |

| Material | C1S +1200g CCNB |

| Surface Finishing : | Hot Foil Stamping,Embossing |

| Shape & Style Options: | Lid and Base Box, 2 Pieces Box with Neck, Clamshell Box, Magentic Box, Folding paper box, Folding Magnetic Box, Drawer Box, Round Tube Box, Other Shape Box, |

| Accessory Options: | PVC /PET/ PP Window, Ribbon, Magnet, EVA, Flocking, EPE Foam/Sponge, Plastic/Paper Tray and ect. |

| Usage: | Skincare Packaging/ Beauty/ Makeup/ Cosmetics packaging |

| Sample: | Free blank sample is available with express freight collected. |

| Delivery Time: | 5~7 days for Digital or Dummy Sample;

15~26 days for Mass Production |

| Shipping port | ShenZhen ,China |

Cosmetic Boxes and Packaging

Boxes and packaging for cosmetics and makeup products are just as important as your product - cosmetic boxes and packaging are an extension of merchandise. Well-crafted, customized cosmetics boxes can make your product stand out on a crowded shelf and dazzle on the densely-packed display rack

Our custom cosmetic boxes and packaging are convenient, easy to use, and protect your valuable product. Our custom cosmetic boxes package and present hundreds of makeup, skin care and other products used by millions of people each and every day.

Our decoration options for packaging boxes for makeup and cosmetic boxes include:

Printing Boxes - Print can be direct print, offset print or flexo print depending on a few factors including quantity, timeline, and desired graphics. Our consultants will direct you based on your needs.

Foil Stamped Boxes - Foil stamping is the process of using a copper or magnesium die that with pressure and heat transfers metallic or matte foil material to a substrate. This is great for Black Boxes that use solid black paper or other Colored Paper Boxes.

Embossed boxes - This is the process of using a copper or magnesium die to "push" the paper out and create texture. This can be registered to art or a "blind" emboss where there is no decoration or graphic being embossed. Embossing is trending in Invitation Boxes currently.

Debossing Boxes - Like embossing we push your design into the paper. The difference is debossing pushes the paper in. This can be a blind deboss, most common, or registered to print. Also very common for plain inner pack boxes a deboss is used as an inexpensive way to create a part number on a box verse having to print.

Coatings - Coating put on top of the printed or plain sheets as a final step or as a mid-step can be applied to your custom box. Examples include Aqueous (water-based) Gloss, Matte, Satin or Soft Touch. UV Gloss and Matte. Film lamination in Matte, Gloss or Soft Touch. Many times we combine a Matte or Soft Touch coating with a contrasting Gloss UV to add depth to your custom packaging.