Manufacturer for Bio Packaging Materials - Wet Pulp, Dry Pulp trays, Inner trays, Eco-Friendly pulp trays – Yinji

Manufacturer for Bio Packaging Materials - Wet Pulp, Dry Pulp trays, Inner trays, Eco-Friendly pulp trays – Yinji Detail:

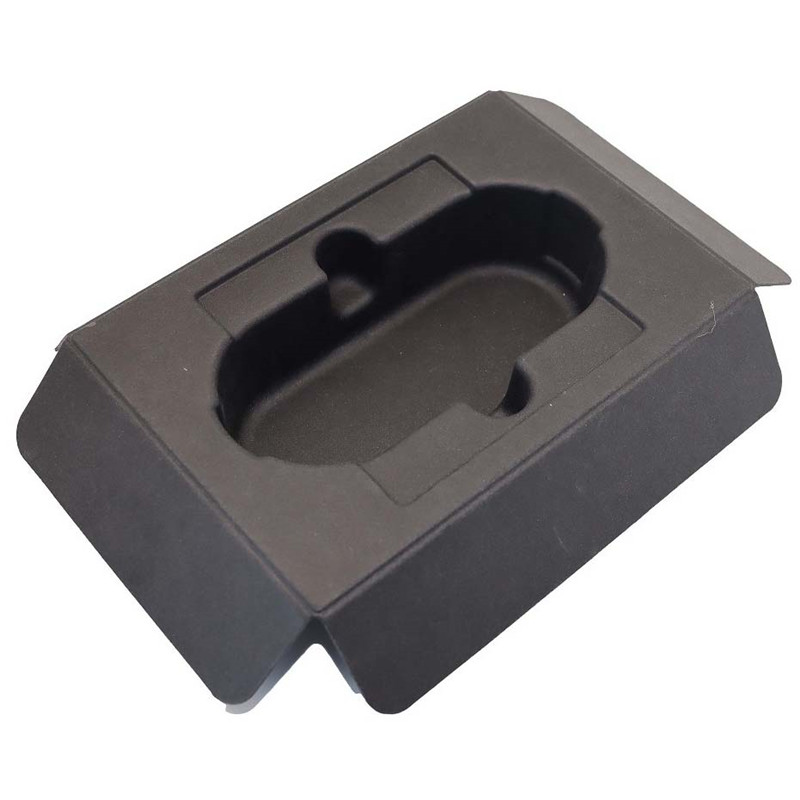

What is a pulp tray?

Pulp trays are made from recycled paper such as newsprint. A pulp tray is an effective packaging element produced from paper pulp. Molded paper pulp products are made by reducing waste paper to a pulp in a process that includes the addition of various property-enhancing agents.

Is molded pulp recyclable?

Molded pulp is already made with postconsumer paper, offering manufacturers a more recyclable and responsible solution than plastic. And after use, molded pulp can be recycled again. In fact, two-thirds of packaging material recovered for recycling is paper — more than the total of glass, metal, and plastic combined.

Is molded pulp packaging expensive?

In one commonly referenced comparison, a stack of 40 molded pulp end caps had a 70% space savings to the same number of EPS (Styrofoam) end caps. The exact space savings will vary for different products, but the fact remains that molded pulp is less expensive and much more efficient to store and transport than EPS.

Production Process

Design

Sampling

Printing

Lamination

Silk Screen

Spot UV

Automatic Cold Foil

DesignDie Cut

Automatic Folding

Handwork

Packing

Pallet

Shipping

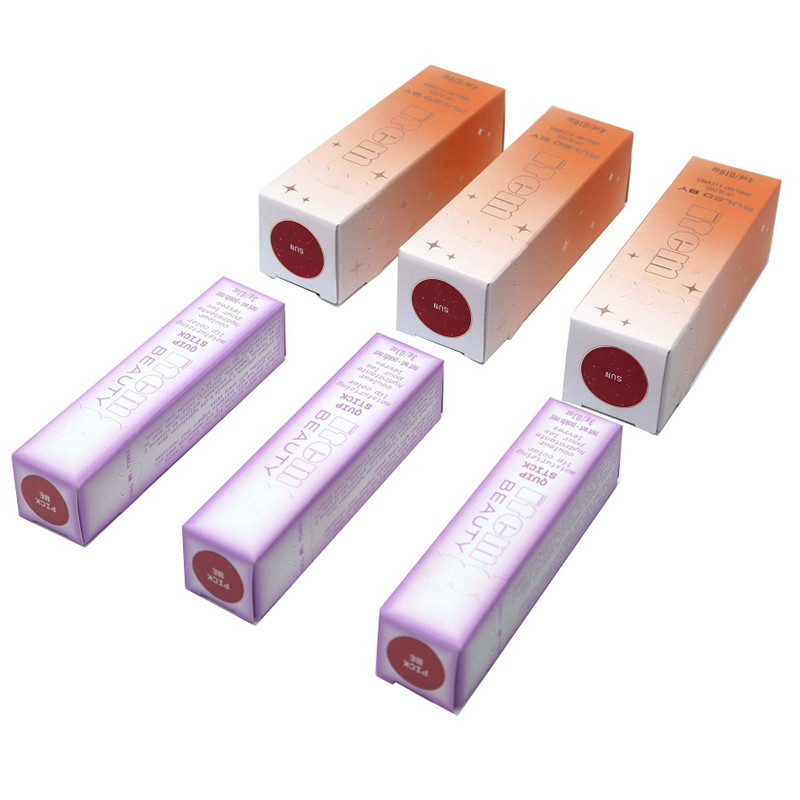

Product detail pictures:

Related Product Guide:

We always continually provide you with the most conscientious customer service, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Manufacturer for Bio Packaging Materials - Wet Pulp, Dry Pulp trays, Inner trays, Eco-Friendly pulp trays – Yinji , The product will supply to all over the world, such as: Nicaragua, Sudan, Casablanca, We will do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.